Arc Welding Processes

Have you been enjoying National Welding Month? We sure have! We’ve covered Shielded Metal Arc Welding and Gas Metal Arc Welding, now it’s time for Flux Cored Arc Welding and Gas Tungsten Arc Welding. Pull up your welding hoods, and read below for all you need to know on the remaining welding processes!

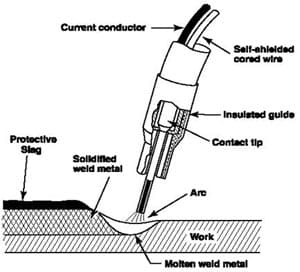

Flux Cored Arc Welding (FCAW) – This welding process is another wire fed based welding process similar to MIG but it solves some of the inherent problems encountered with MIG welding. First off instead of a solid wire as used in MIG welding, FCAW uses a wire which contains flux in the center. Since the wire already has flux contained inside it generates its own shielding gas much the same way the welding rod does with Stick. This eliminates the need for an external shielding gas and makes it suitable for welding in outdoor situations. There are some types of flux core wire that do require an external shielding gas but we are focusing on the type that does not require any. The drive mechanism and gun used in FCAW is virtually identical to MIG welders and most all MIG welders can be used to run Flux Core wire just by switching out the welding wire and changing some settings. Flux Core welding also solves the problems of lack of fusion that is often encountered in MIG. FCAW’s welding penetrates extremely well and can be used to weld thick metal very fast and efficiently. Large fabrications and heavy construction industries often use FCAW as one of their main welding processes since it is so fast and can be used indoors as well as outdoors in the field. One limitation of FCAW is that it can only be used to weld ferrous metals and some nickel based alloys.

Gas Tungsten Arc Welding – Commonly referred to as TIG (Tungsten inert gas) or its older name Heliarc Welding. GTAW is the one manual welding process that is capable of welding almost any metal or alloy. It is the welding process of choice when it comes to critical high precision welds and as such requires the most skill to use. TIG welding uses a torch with a non-consumable tungsten electrode that is used to create an arc between the tungsten and the base metal which forms a molten weld puddle. After the welder establishes the weld puddle a filler wire that matches the base metal is used to add metal to the puddle and weld the metals together. The TIG welding process uses a variety of external shielding gases such as Argon, Helium or mixes. The choice of shielding gas and filler wire selection is determined by what type of metal you are welding. As noted this welding process is usually considered the most difficult and requires a high degree of skill since it is most often used to weld metals that are difficult to weld in the first place.

Whew! Do you feel like a welder yet?

Learn Flux Cored and Gas Tungsten Arc Welding today!

More on Welding:

[wpu_silo links=’21’]